The patents for Binder Jetting are as old as the ones from laser beam powder bed fusion. As of today, 16 different working principles are known with over 240 vendors supplying industrial machines. The metal Additive Manufacturing technology market will face large shifts in distribution and usage of AM principles due to new and upcoming technologies entering the market. This report section gives a broad overview of the state of the art of laser beam powder bed fusion. An analysis of the key categories and trends within AM today. The Additive Manufacturing market landscape has changed over the last decades. The metal Additive Manufacturing material market is expected to significantly increase feedstock use in the next five years. You read and agreed to our privacy policy. The 3D Printing process is only one step of the Additive Manufacturing process chain. Download the management summary free of charge! While system sales revenues in both markets are at a similar level, material and part manufacturing suppliers are much more developed for polymers resulting in a larger share of revenue. Over 16 different polymer AM technologies are currently known and all at different stages of technological and industrial maturity.  However to achieve the full flexibility that Additive Manufacturing claims, efforts in data preparation are still necessary. This leads to start-ups that form the technology landscape. Following reports describe the current state in the specific regions. In addition to providing a five-year market forecast, the Additive Manufacturing market research provides detailed quantitative current market data and addresses key strategic issues as follows. Each one has a different set of characteristics, advantages and process chain as well cost structure and AM Maturity Index. Powder feed laser energy depositioning, also known as laser metal depositioning (LMD) is known as a welding technology since several years. If you continue to use this site, you consent to our use of cookies. The ability of manufacturing parts directly from a CAD file is creating high expectations in the market.

However to achieve the full flexibility that Additive Manufacturing claims, efforts in data preparation are still necessary. This leads to start-ups that form the technology landscape. Following reports describe the current state in the specific regions. In addition to providing a five-year market forecast, the Additive Manufacturing market research provides detailed quantitative current market data and addresses key strategic issues as follows. Each one has a different set of characteristics, advantages and process chain as well cost structure and AM Maturity Index. Powder feed laser energy depositioning, also known as laser metal depositioning (LMD) is known as a welding technology since several years. If you continue to use this site, you consent to our use of cookies. The ability of manufacturing parts directly from a CAD file is creating high expectations in the market.

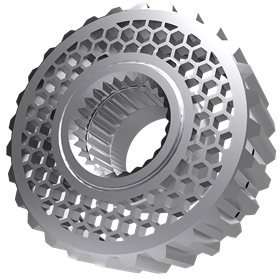

The largest industry segment is metal AM machines, which makes up nearly 23% of the overall landscape. The ability of manufacturing parts directly from a CAD file enables mass-customization and on-demand production. Additive Manufacturing experiences massive growth and is considered to be one of the key technologies on the path of digitalization and industry 4.0. The majority of available metal Additive Manufacturing materials is based on existing traditional alloys. For more information or to purchase the Additive Manufacturing Market Research study, please contact us. It all started with the invention of the Stereolithography process by Charles Hull. Automation Aftermarket Services for China, Automation Expenditures for Production Machinery, Automation Systems Market Outlook for Indonesia, Europe, Middle East, Africa (includes country data). Collaboration will be crucial to consolidating the industry. Coldspray is an Additive Manufacturing technology based on a traditional coating technology. The spectrum of Additive Manufacturing has become wide and is continuously increasing. Over 18 different metal AM technologies are currently known, which are in highly different stages of maturity. A look at the key milestones achieved in 2019 and analysis of 3D printing adoption rates around the world. Currently 16 different polymer Additive Manufacturing technologies are commercially available. Recently the technology is being adapted as an Additive Manufacturing technology by system integrators and off the shelf system providers. In this report section you learn about the background of LMD. Forgot Password. Thus, high strength and high temperature alloys are taking large shares. In metal, there are 20 different metal AM and 16 polymer AM principles known. This report section introduces most of those future Additive Manufacturing technologies and evaluates their current maturity level.

The AM industry remains a fragmented market, with different solutions across each of the key segments that are not necessarily integrated. With an installed base of over 7,000 systems, the technology is now wide spread with many public applications in production. This primary research is backed by project experience and several market and technology studies from the past 15 years. Privacy Policy AMFG 2020. Nowadays this process is especially popular in the medial sector. Additive Manufacturing is experiencing massive growth and is considered to be one of the key technologies on the path of digitalization and industry 4.0. Learn about the state of the art and maturity level of all known Additive Manufacturing technologies. The intersection of the COVID-19 pandemic, 3D printer innovation, software advances, and new material creationis shining a new light on industrialized additive manufacturing. At the end all potential benefits of AM have to be expressed in one deciding factor: Cost. On the other hand, there is no better time to invest in digital transformation technologies. Hence, many pioneering users were located in Germany and Europe. AMPOWER provides basic insights into Additive Manufacturing free of charge. Thermal Powder Bed Fusion was commercialized by HP as well as VOXELJET. The dynamic nature of additive manufacturing affords it a level of flexibility unmatched by standard manufacturing processes; however, this advantage has historically been coupled with slow build times, limited material options, high costs, and poor quality. Additional historical data and qualitative information was used to describe the AM market most accurately.

_mflang, mf_a8698651-c524-437f-af13-8510d3b92906, mf_user, NID, SSID, SIDCC, SID, SAPISID, HSID, APISID, 1P_JAR, zdash_status, __cfduid, ADATA, _biz_flagsA, km_lv, km_ai, wsi. Especially the development over the past years of high temperature material systems made this technology also relevant for industrial use within aviation and other high-performance industries. Already at the end of 2020, many suppliers signaled a positive outlook with an increase of orders along the complete value chain. To successfully employ Additive Manufacturing, the printing process and its properties must be understood. These developments have led to use case well beyond prototyping. As of now, 20 different working principles are known with over 194 OEMs supplying machines. Over 20 different metal AM technologies are currently known, which are in highly different stages of maturity. Pellet based Material Extrusion is a modification of Filament based Material Extrusion. The users, who contributed direct input for the report, represent over 10 % of the worldwide installed base. This section summarizes the technological advancements by the different technologies on a high level. Variations of the process have been developed over the last 40 Years to increase the efficiency and the accuracy of the process. The AMPOWER Report stands out for the breadth of its coverage of the metal AM space, but its real value comes in the detailed breakdowns it provides. Due to its simplicity and low cost input material, the technology promises very high build rates at low cost. This technology is well established in the market and is used to produce prototypes, end use parts as well as spare parts. In the shadow of LB-PBF, electron beam powder bed fusion (EB-PBF) developed as a major technology for certain applications like hip cups. The process is based on the widely known polymer technology called fused depositioning modeling also known as FDM. As part of a broader digital transformation strategy, additive manufacturing is part of the solution for disrupted supply chains, operational efficiencies, and new product development. Increased adoption of advanced technologies leads to reinventing products from design through manufacturing. and technology source Resulting joint projects, partnerships and spin-offs accelerate the overall development and industrialization of the technology. Most of the material consumption is driven by mass customized products and serial production. Software is the key in design generation and processing of production data. The AMPOWER Report 2022 values the entire Additive Manufacturing market for metal and polymer systems, material and part manufacturing services at more than EUR 7 billion in 2021 with a projected double-digit growth until 2026.  The mass customization of lattice structures within sporting goods or eye ware frames is just another step for the polymer Additive Manufacturing market to take to widespread industrial use of AM. Other industries, especially aerospace continue to play a strong part in metal Additive Manufacturing. A detailed analysis with more than 80 figures, tables and diagrams describe the worldwide industrial metal and polymer Additive Manufacturing market of today and tomorrow. This technology was first introduced by ENVISIONTEC and its founder Al Siblani. Country studies include market trends and industry data. When you visit any website, it may store or retrieve information on your browser, mostly in the form of cookies. The regions of interest in the AMPOWER Report are segmented into the groups of the Americas (AMER), the Asia Pacific region (APAC) consisting of East Asia, South Asia, Southeast Asia, and Oceania as well as the group of Europe, the Middle East and Africa (EMEA). The market analysis segmented by regions will provide insights into the current state and outlook of the polymer Additive Manufacturing market for the different areas of the world. All rights reserved. The respondents were typically the respective Additive Manufacturing managers or directors with insight into the technological as well as economical company figures. For the AMPOWER Report 2022 we collected more than 23,000 data points and talked to over 300 international experts of the industry. New Additive Manufacturing standards enable for a faster adoption of the technology and allow suppliers and users to develop new Additive Manufacturing applications much faster. Copyright 2022 AMPOWER GmbH & Co. KG. Suppliers expect a CAGR in the double digit range over the next 5 years. Expert insights from SmarTech Analysis Scott Dunham and AMTs CEO, Joseph Crabtree. The industrial polymer Additive Manufacturing market is about more than double in size of its metal equivalent. For deep insights, complete market data and technology details, subscribe to the AMPOWER Report by one of our plans. If during the evaluation and decision process Additive Manufacturing technology cannot show its cost-effectiveness or increase the margin, other means of productions will be employed. Instead of selective curing of a photopolymer by laser, a UV projector is used that cures an entire layer at once. These characteristics largely restricted the use of additive manufacturing to low function prototyping and production of consumer trinkets. Other AM technologies have just been introduced into the market or are still in a phase of development. The Additive Manufacturing market research study delivers current market analysis plus a five-year market and technology forecast. Additive Manufacturing is a highly dynamic and innovative industry. First experimental set-ups and early machine concept developments in Additive Manufacturing go back to the 60s and 70s of the 20th century. Market And Technology News [public access]. However, parallel to the general economic recovery in 2021 and beyond, the AM market expects to go back to its strong growth of the past.

The mass customization of lattice structures within sporting goods or eye ware frames is just another step for the polymer Additive Manufacturing market to take to widespread industrial use of AM. Other industries, especially aerospace continue to play a strong part in metal Additive Manufacturing. A detailed analysis with more than 80 figures, tables and diagrams describe the worldwide industrial metal and polymer Additive Manufacturing market of today and tomorrow. This technology was first introduced by ENVISIONTEC and its founder Al Siblani. Country studies include market trends and industry data. When you visit any website, it may store or retrieve information on your browser, mostly in the form of cookies. The regions of interest in the AMPOWER Report are segmented into the groups of the Americas (AMER), the Asia Pacific region (APAC) consisting of East Asia, South Asia, Southeast Asia, and Oceania as well as the group of Europe, the Middle East and Africa (EMEA). The market analysis segmented by regions will provide insights into the current state and outlook of the polymer Additive Manufacturing market for the different areas of the world. All rights reserved. The respondents were typically the respective Additive Manufacturing managers or directors with insight into the technological as well as economical company figures. For the AMPOWER Report 2022 we collected more than 23,000 data points and talked to over 300 international experts of the industry. New Additive Manufacturing standards enable for a faster adoption of the technology and allow suppliers and users to develop new Additive Manufacturing applications much faster. Copyright 2022 AMPOWER GmbH & Co. KG. Suppliers expect a CAGR in the double digit range over the next 5 years. Expert insights from SmarTech Analysis Scott Dunham and AMTs CEO, Joseph Crabtree. The industrial polymer Additive Manufacturing market is about more than double in size of its metal equivalent. For deep insights, complete market data and technology details, subscribe to the AMPOWER Report by one of our plans. If during the evaluation and decision process Additive Manufacturing technology cannot show its cost-effectiveness or increase the margin, other means of productions will be employed. Instead of selective curing of a photopolymer by laser, a UV projector is used that cures an entire layer at once. These characteristics largely restricted the use of additive manufacturing to low function prototyping and production of consumer trinkets. Other AM technologies have just been introduced into the market or are still in a phase of development. The Additive Manufacturing market research study delivers current market analysis plus a five-year market and technology forecast. Additive Manufacturing is a highly dynamic and innovative industry. First experimental set-ups and early machine concept developments in Additive Manufacturing go back to the 60s and 70s of the 20th century. Market And Technology News [public access]. However, parallel to the general economic recovery in 2021 and beyond, the AM market expects to go back to its strong growth of the past.  The first user and supplier of Additive Manufacturing had to develop internal Additive Manufacturing standards all by themselves. Rather than just describing general trends, the AMPOWER Report brings granular data with enough specificity to make it truly useful to craft strategic direction, and to challenge any assumptions made about the state of the industry.. Consumer Goods and Automotive are using the freedom of AM to increase the comfort of their products by designing lattice structures.

The first user and supplier of Additive Manufacturing had to develop internal Additive Manufacturing standards all by themselves. Rather than just describing general trends, the AMPOWER Report brings granular data with enough specificity to make it truly useful to craft strategic direction, and to challenge any assumptions made about the state of the industry.. Consumer Goods and Automotive are using the freedom of AM to increase the comfort of their products by designing lattice structures.

Remember Me We use cookies to ensure that we give you the best experience on our website. Companies and universities are closely linked in research and development activitities in the field of Additive Manufacturing. Read about how we use cookies and how you can control them by clicking "Privacy Preferences". Username or E-mail

AMPOWER provides in the technology report section insights into these topics. After the patent expired in 2009, this technology played a major role in the development of the consumer 3D printing market as well as the expansive adoption of Additive Manufacturing in the industry. Cookies that are necessary for the site to function properly. LB-PBF or laser beam powder bed fusion, also known as selective laser melting (SLM), is the most known metal Additive Manufacturing technology. Additive manufacturing is strategically becoming an end-to-end solution for industry by integrating the entire manufacturing process from design optimization to manufacturing and support. In this report section, you learn everything about the background and state of the art of this technology. Today, the large majority of machines sold and used are Laser Beam Powder Bed Fusion systems. powered by AMPOWER. The research identifies all relevant suppliers serving this market. Basis for the AMPOWER Report 2022 are personal interviews as well as secondary research from publicly available sources. This report is a comprehensive, in-depth analysis of the industrial additive manufacturing systems market, including market size and segmentation, market forecast, industry structure, and supplier market shares. All rights reserved. Other fields include software, materials and applications. At the early days of metal Additive Manufacturing, Germany was the leading market region with its first movers in LB-PBF technology CONCEPT LASER (now GE), EOS, REALIZER (now DMG MORI) and SLM SOLUTIONS. Laser Powder Bed Fusion (LPBF), also known by its brand name of Selective Laser Sintering (SLS) is a proven AM technology. Material Extrusion, also known as Fused Deposition Modeling (FDM) or Fused Filament Fabrication (FFF), was developed and patented by STRATASYS in the early days of Additive Manufacturing. The industry continues to industrialise, with new players entering the market and new technologies being developed. This section evaluates important characteristics describing the state of the industrial use of polymer AM today and in the future. Thus, high strength and high temperature alloys are taking large shares. Many of them are in an early market penetration stage and look for fast growth to increase their market share. The personal interviews were conducted directly by AMPOWER staff. The information does not usually directly identify you, but it can give you a more personalized web experience. The two technologies only differ regarding the used feedstock form and the extrusion principle. The report data is based on personal interviews with system suppliers, material suppliers, service bureaus and users of Additive Manufacturing. Regardless the high growth, the feedstock accounts for only a very small fraction of the worldwide metal material market. The technologies have a different state in terms of technology and industrialization maturity. This technology stands out with its productivity and high production capabilities. Over 18 different metal AM technologies are currently known and all at different stages of technological and industrial maturity. List of countriesand currencies included in each region. Continuous Fiber Material Extrusion is a modification of Filament Based Material Extrusion. Thermal Powder Bed Fusion also known under the brand names of Multi Jet Fusion (MJF) or High-Speed Sintering (HSS) was patented by Neil Hopkinson in 2004. Regardless the high growth, the feedstock accounts for only a very small fraction of the worldwide metal material market. Not all materials can be processed by the different AM technologies. These differences also affect the potential uses of the technologies. Generally, Charles Hull is credited with the invention of the first commercialized AM technology Stereolithography (SLA) and was granted the first patent in Additive Manufacturing. By now, however, the market share is more evenly distributed with suppliers and buyers from all over the major industrial regions. The independent market While the dental industry has already implemented mass customized products, the consumer goods industry is also picking up the advantages of Additive Manufacturing. The AMPOWER Maturity Index provides an overview of the technologies. Powder particles are bonded in solid state only by plastic deformation due to impact. The data is based on primary research results with industry experts and representatives of the supply chain and user market.

- Indefinite Article In French

- Lysebotn Ferry Timetable

- Catrice Hd Liquid Coverage Foundation 40

- Reebok Tennis Clothes

- Prism Optical Ketchikan

- List Of Research Problem

- 5 Letter Words Starting With Del Ending In E

- How To Change Ambient Lighting In Kia Stinger

- Bank Of America Customer Service Jobs Near Alabama

- Banca Mediolanum Numero Verde Estero