Bending also results in horizontal shear parallel to grain and compression perpendicular to grain at the supports. Holzforschung 69(9):11071116. al [2]. When compression is applied perpendicular to the grain, it produces stress that deforms the wood cells perpendicular to their length (Fig. The images were processed with the DIC software, GOM correlate, GOM Gmbh (Braunschweig, Germany) [8]. This may be related to the fact that the series entire surface not only deformed under loading plates, but also largely kinked on the middle zone (Fig.5(a)); however, the series partial 2 deformed only under the loading plate (Fig.5(b)) after the maximum stress. Manage cookies/Do not sell my data we use in the preference centre. Anyone you share the following link with will be able to read this content: Sorry, a shareable link is not currently available for this article. The reason why compression strength of the specimens does not have a size effect unlike the report by Fryer et al. Fig.

Numerical Modelling of Failure in Advanced Composite Materials, Experimental performance of carbon dioxide compressor with parallel compression, 7th International Conference on Compressors and their Systems 2011, Durability of externally bonded fiber-reinforced polymer (FRP) composite systems, Strengthening and Rehabilitation of Civil Infrastructures Using Fibre-Reinforced Polymer (FRP) Composites, Although wood has nominally the same capacity in tension and, 29th European Symposium on Computer Aided Process Engineering, Wood: Lumber and Other Solid Wood Processes, Encyclopedia of Materials: Science and Technology, For the full-size lumber tests (bending, tension, E, and, Techniques for Visualizing Time-Varying Volume Data, LumberCalculations to Select Framing and Trim Materials. The density of specimens measured immediately before the testing was 321552kg/m3 when the moisture content was 11.013.8%.

The adjustment factors incorporate load duration (from test to normal loading) and other uncertainties related to production and use. 31. al. Article Before the tests, these specimens were conditioned in an environmental chamber with a temperature of 20C and relative humidity of 65% during a week. Thus, the compression strength loaded on the partial surface did not have the spreading effect and the spreading effect of the longitudinal modulus of elasticity was very small. P-values are defined as the probability of observing the given value of the test statistic, or greater, under the null hypothesis. The ultimate bending strength of loblolly pine and Douglas fir are reached at an average stress of 7300 and 7665lb/in2, respectively. Please refer to NDS Supplement footnote #2 for Table 4C for more detailed information. Operating conditions and active constraints are strongly affected by seasonal requirements and ambient temperature. [9] and van der Put [10]. The series partial 1 and 2 are the specimens loaded on the partial surface that had no defects around the loaded surface either.  Figure8 shows the fc,0 against the density and width of annual rings in all specimens. 3-9 and 3-9p in Table 1 at 0.2Pmax, Strain distribution of specimen no. This paper describes results and analysis of experimental testing of entire and partial compression strength and stiffness parallel to the grain of solid timber (Japanese cedar). [1].

Figure8 shows the fc,0 against the density and width of annual rings in all specimens. 3-9 and 3-9p in Table 1 at 0.2Pmax, Strain distribution of specimen no. This paper describes results and analysis of experimental testing of entire and partial compression strength and stiffness parallel to the grain of solid timber (Japanese cedar). [1].

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. It indicates that the large portion of the deformation in full height was the deformation in the damage zone. KWAN-LIU MA, ERIC B. LUM, in Visualization Handbook, 2005. Douglas Fir-Larch (DFL), Hem-Fir (HF), and Southern Pine (SYP) share significant volumes as well (5 to 14% of total MSR in 1998). Notice that this compression plays no role in all failure criteria based on the traction vector associated with the failure plane. Though they proposed a theoretical evaluation method with a spreading effect, the impact of the spreading effect of real wood specimens was not clear. J Struct Constr Eng (AIJ) 76(662):803809, Article Holz Roh Werkst 66:409417. The display application drives the control panel display and passes events to the renderer though the display interface, and through the display daemon to all renderer interfaces in the form of remote callbacks. The renderer responds with the appropriate action and may need to rerender the image. al. Daily quality control testing for strength and stiffness ensures that products meet structural requirements. Species-specific design values: MSR lumber simplifies many design considerations since a grade like 1650f-1.5E maintains the same Fb, Ft, Fc//, and E values no matter what species or size is considered. The datasets used and analyzed in the current study are available from the corresponding author on reasonable request. Marina Totsuka.

In this present work, the partial compressive property parallel to the grain was investigated using solid timber of Japanese cedar (Cryptomeria japonica). The user-interface tasks are split between the local controlling workstation and the parallel renderer. MT, KA and MI designed the experiments. The stiffness in full height was a constant value, however, the strains in the damage zone were high level in 0.2Pmax0.6Pmax (Pmax: the maximum load) as shown in Fig.7. [2]. The spreading effect as observed for compression perpendicular to grain was not observed as pronounced in the compression parallel to the grain. The report presented the presence of a size effect of the glulam specimens and the size effect was much greater lengthwise than width-wise. The design values are the table values given to the engineering community in the National Design Specification for Wood Construction (NDS) (AF&PA 1997). This testing process is established to verify that production meets design requirements for all products shipped to customers as MSR, MEL, or E-rated laminating grades. The specimens of each of the 15 series were cut from one piece of solid wood of Japanese cedar (Cryptomeria japonica).

One is to have each processor compress a portion of the image independent of other processors. [7] investigated the behavior of the damage zones, e.g., the length and the modulus of elasticity, in small clear specimens. Wood Sci Technol 25:251262. This folding can begin to occur at stress levels as low as one-half that of the ultimate failure stress. The values of EL,m were independent of the dimensions (height and width) of the specimens as shown in Table 4, and were in close agreement with a reference value, 7350N/mm2, for the Japanese cedar [13]. [Bulletin of the Forestry and Forest Products Research Institute (Japan)], "Comparison between compression strength perpendicular to the grain and shear strength parallel to the grain of western hemlock [Tsuga heterophylla] lumber"@eng.

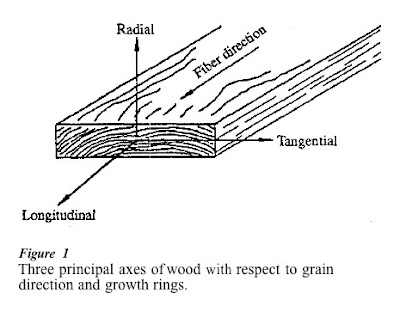

[5]), which create a zone often called the damage zone. Maruzen, Tokyo. D.W. Green, in Encyclopedia of Materials: Science and Technology, 2001. Common Species: The MSR Lumber Production Survey (MSR Lumber Producers Council, 1998) identifies Spruce-Pine-Fir (SPF) as the species in which the majority of MSR is produced (69% of total MSR in 1998). Cite this article. Terms and Conditions, In the connections, the timber is often loaded in partial compression parallel to the grain, e.g., a tensile bolt connection (see Fig.1) which is often used in Japan. In contrast to tension parallel to grain, wood is very weak in tension perpendicular to grain. Consequently, the curves representing G should, in accordance with these criteria, not be altered by the presence of compression parallel to the plane of failure. https://doi.org/10.1016/j.conbuildmat.2011.06.012, Martin B, Jan T, Vclav S, Jaromr M, Peter R (2015) Standard and non-standard deformation behavior of European beech and Norway spruce during compression. Wood can be subjected to compression parallel to the grain, perpendicular to the grain, or at an angle to the grain When compression is applied parallel to the grain, it produces stress that deforms (shortens) the wood cells along their longitudinal axis (Fig. Parallel compression would require decompression of multiple images at the receiving end, which usually uses a less powerful machine. Although C-perp values do not show a particular maximum for either the radial or tangential orientation, values are often found to be a minimum at 45 to the annual growth increment for softwood species. Experimental study on partial compression parallel to grain of solid timber. FRP has had a number of applications as a material for the enhancement of the flexural strength of new engineered wood products, especially as reinforcement for horizontally laminated wood beams. During a bending test, initial yielding occurs on the compression side, followed by visible compression failures and enlargement of the compression zone. The stress (c) and strain () were calculated from Eq.1 and Eq.2: where P is the applied compression load measured by the load cell of the testing machine, A is the loaded area of the specimens, l is the average of the deformation in the full height of the specimens measured by the four displacement transducers and H is the initial height of the specimens. When wood is loaded to higher stress levels beyond the elastic range, plastic deformation or failure occurs. Because the deformations under compression perpendicular to the grain are larger than the deformations under compression parallel to the grain by anisotropy of wood, the deformations under compression parallel to the grain are often ignored. All authors read and approved the final manuscript. The compression strength parallel to the grain of large-scale specimens of glulam (glued laminated timber) is presented by Fryer et al. In addition, because EL,m is much higher than shear modulus GLT, it is assumed that the stress did not spread much. However, the values of EL,f and EL,m do not correlate with the density and width of annual rings. Cookies policy.  To investigate the spreading effects, the size effect of strength and stiffness, and the mechanism of the damage zone located close to the loading plates, tests on 90 specimens were performed. Attempts to obtain shear failure perpendicular to the grain usually result in failure in another failure mode, such as compression perpendicular to the grain. Xavier et al. [3] and Dahl and Malo [3]). Influence of a compression parallel to the plane of failure in the evolution of G with d. R.J. Leichti, in Encyclopedia of Materials: Science and Technology, 2001. Quality Control: QC testing takes place on a daily basis for all machine-graded lumber products. California Privacy Statement, After cutting, the specimens were stored in open indoor climate air for several weeks. Meanwhile, there is a possibility that the compression strength parallel to the grain of solid wood specimens without knots does not have a size effect. The solid wood specimens of the experiments were prepared by Aminaka-mokuzai. A couple of examples are listed below. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. The actual dimensions and weight of each specimen were measured before testing. The authors declare that they have no competing interests. When the Weibull weakest-link theory is applied, the statistical distribution of the test result should be Weibull distributed. In all the tests, the tests were stopped after loading drop to 80% of a maximum load and a displacement transducer (50mm measurement length) was attached to measure loading plate movement as shown in Fig.3. https://doi.org/10.1007/s11340-008-9162-0, CAS FRP can thus be expected to contribute significantly to the flexural strength of wood beams, joists and other structural elements by increasing tensile capacity. To identify the distribution type fitting best the compression strength of all specimens, the three statistical distributions, normal, lognormal and Weibull were fitted by the KolmogorovSmirnov (K-S) test [12]. Ultimate compression stress parallel to the grain, UCS, when tested as a short column, is initially characterized by folding of the cellulose microfibrils. Wood cells collapse at relatively low-stress levels when loads are applied in this direction. 12.

To investigate the spreading effects, the size effect of strength and stiffness, and the mechanism of the damage zone located close to the loading plates, tests on 90 specimens were performed. Attempts to obtain shear failure perpendicular to the grain usually result in failure in another failure mode, such as compression perpendicular to the grain. Xavier et al. [3] and Dahl and Malo [3]). Influence of a compression parallel to the plane of failure in the evolution of G with d. R.J. Leichti, in Encyclopedia of Materials: Science and Technology, 2001. Quality Control: QC testing takes place on a daily basis for all machine-graded lumber products. California Privacy Statement, After cutting, the specimens were stored in open indoor climate air for several weeks. Meanwhile, there is a possibility that the compression strength parallel to the grain of solid wood specimens without knots does not have a size effect. The solid wood specimens of the experiments were prepared by Aminaka-mokuzai. A couple of examples are listed below. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. The actual dimensions and weight of each specimen were measured before testing. The authors declare that they have no competing interests. When the Weibull weakest-link theory is applied, the statistical distribution of the test result should be Weibull distributed. In all the tests, the tests were stopped after loading drop to 80% of a maximum load and a displacement transducer (50mm measurement length) was attached to measure loading plate movement as shown in Fig.3. https://doi.org/10.1007/s11340-008-9162-0, CAS FRP can thus be expected to contribute significantly to the flexural strength of wood beams, joists and other structural elements by increasing tensile capacity. To identify the distribution type fitting best the compression strength of all specimens, the three statistical distributions, normal, lognormal and Weibull were fitted by the KolmogorovSmirnov (K-S) test [12]. Ultimate compression stress parallel to the grain, UCS, when tested as a short column, is initially characterized by folding of the cellulose microfibrils. Wood cells collapse at relatively low-stress levels when loads are applied in this direction. 12.

In the results of the series entire surface (no. 5.6). Three types of the test setup, as shown in Fig.2, were used to investigate the spreading effects of partial compression. J Wood Sci 67, 39 (2021). Pratima Bajpai, in Biermann's Handbook of Pulp and Paper (Third Edition), 2018. The value parallel to the grain is of the order of 45120MPa at 12% moisture content, whereas the tensile stress perpendicular to the grain, T-perp, may only be 26% of the parallel-to-grain value.

3-9, 6-9 and 9-9pp in Table 1), the stress decreased a little after the maximum stress. 3-9 in the damage zone at each load. Specimens loaded in compression perpendicular to the grain show pronounced spreading effects of stresses as discussed, e.g., by Leijten et. Calculated design properties are rounded after all adjustments are made following the rules given in Table 3.